Line Cutterz Auto Glass Breaker – 2023

We teamed up with Line Cutterz yet again to introduce their patented blade technology to the automotive world with this seat belt cutter and auto glass breaker duo. The device is designed to clip to car visors and be a visible, easy-to-grab tool in the event of an emergency. It can also be looped onto car keychains using the device’s blade guard clip. Multiple prototypes and function tests led us to create this pocket-sized, dependable automotive tool.

Design and Engineering

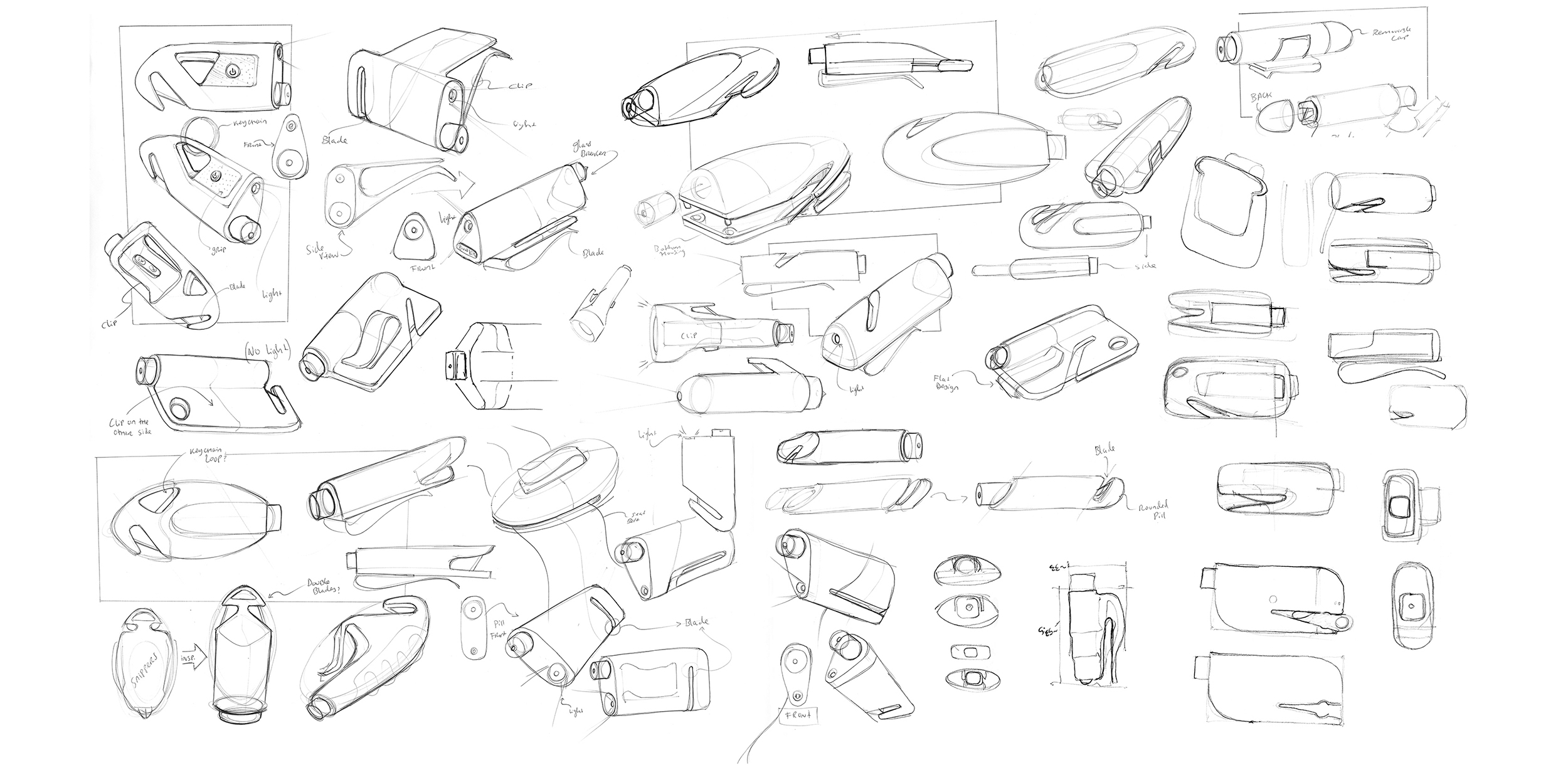

We began with sketching – experimenting with where the blade would go, where the glass breaker would be, and how the product would be held. We landed on a design that is compact, easy to hold, and playfully reminiscent of a fish’s mouth.

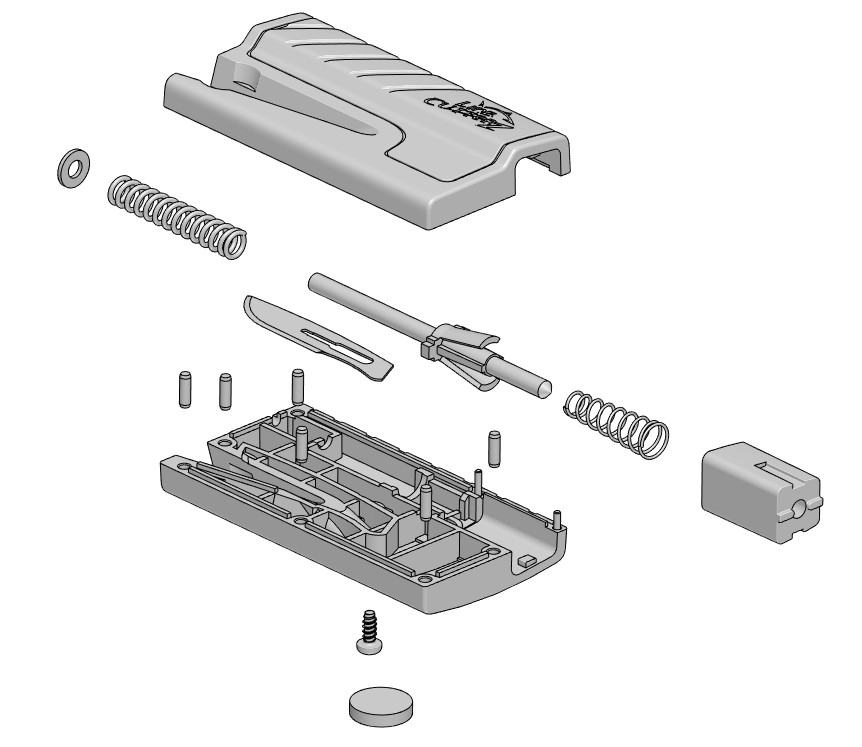

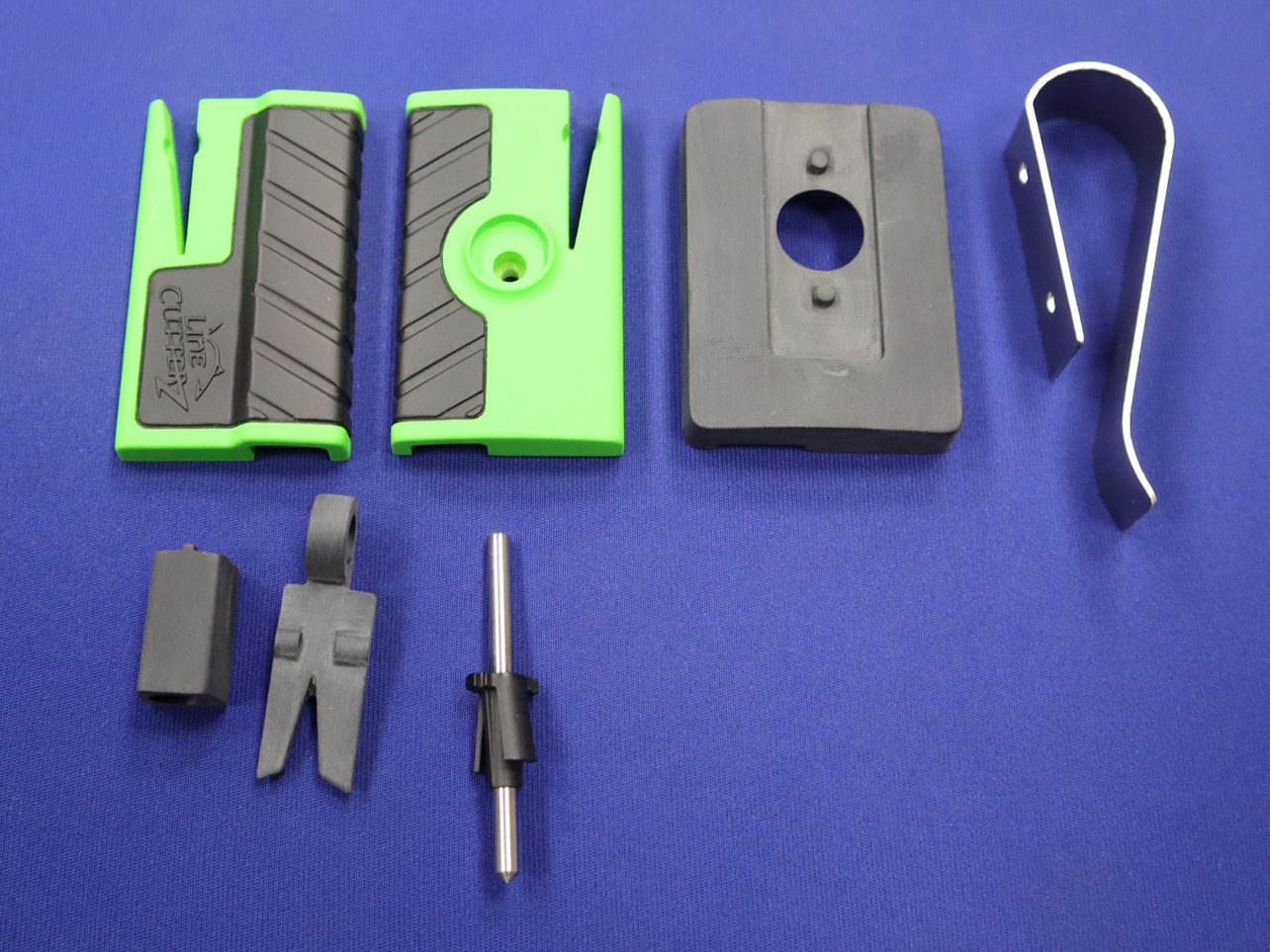

We took to 3D and made some more refinements to our concept. Then we rapid-prototyped several housings with swappable parts that could be compared for belt cutting performance, glass breaking performance, size, and overall experience.

Design and Engineering

We began with sketching – experimenting with where the blade would go, where the glass breaker would be, and how the product would be held. We landed on a design that is compact, easy to hold, and playfully reminiscent of a fish’s mouth.

We took to 3D and made some more refinements to our concept. Then we rapid-prototyped several housings with swappable parts that could be compared for belt cutting performance, glass breaking performance, size, and overall experience.

Once we were happy with the general layout and form of the glass breaker/seatbelt cutter, we engineered the glass breaking mechanism. The device automatically fires a steel striker at the window once you press down hard enough on the glass. The design and materials used in the mechanism were carefully considered to guarantee the device would be strong enough to break a window on the first try, and robust enough to work multiple times. No corners were cut in this potentially life-saving device.

We made multiple high-fidelity engineering prototypes until we got the design of the glass breaker just right. To make sure the device would never fail in the field, we performed countless glass breaking and seatbelt cutting tests. Line Cutterz even assisted by finding a scrapyard and testing the glass breaker on actual car windows.

It was also important that we made sure the device wouldn’t fly out of its visor clip in the event of a crash. We designed a crash-testing rig that we could mount the visor clip to, and we used it to carry out crash tests in all possible crash directions. We mounted an accelerometer to the rig to make sure the crashes were seeing a realistic amount of force.

Our final design for the Auto Glass Breaker is dependable and easy to use. It’s an awesome expansion of the Line Cutterz brand. It’s rugged, gets the job done, and goes where you and your vehicle go. The Line Cutterz Auto Glass Breaker is a small yet powerful tool that can stay out of sight when not needed, but be quickly accessible when it counts.