Klooji – 2018

Klooji (noun): a bag-toss game made from many parts kludged together.

That’s how the creator of Klooji first introduced us to his homemade game. Having sold a version of the game from his garage for several years, he wanted to finally take it to mass production. We helped him strategically update the design for specific manufacturing processes while keeping all the elements that make Klooji cool: portability, quick setup, and (of course) castles.

The final product captures the spirit of the game in an injection-molded design. It’s carried like a suitcase, deploys in seconds, and is a unique party game for the whole family. What started in one man’s garage is now in backyards across the world.

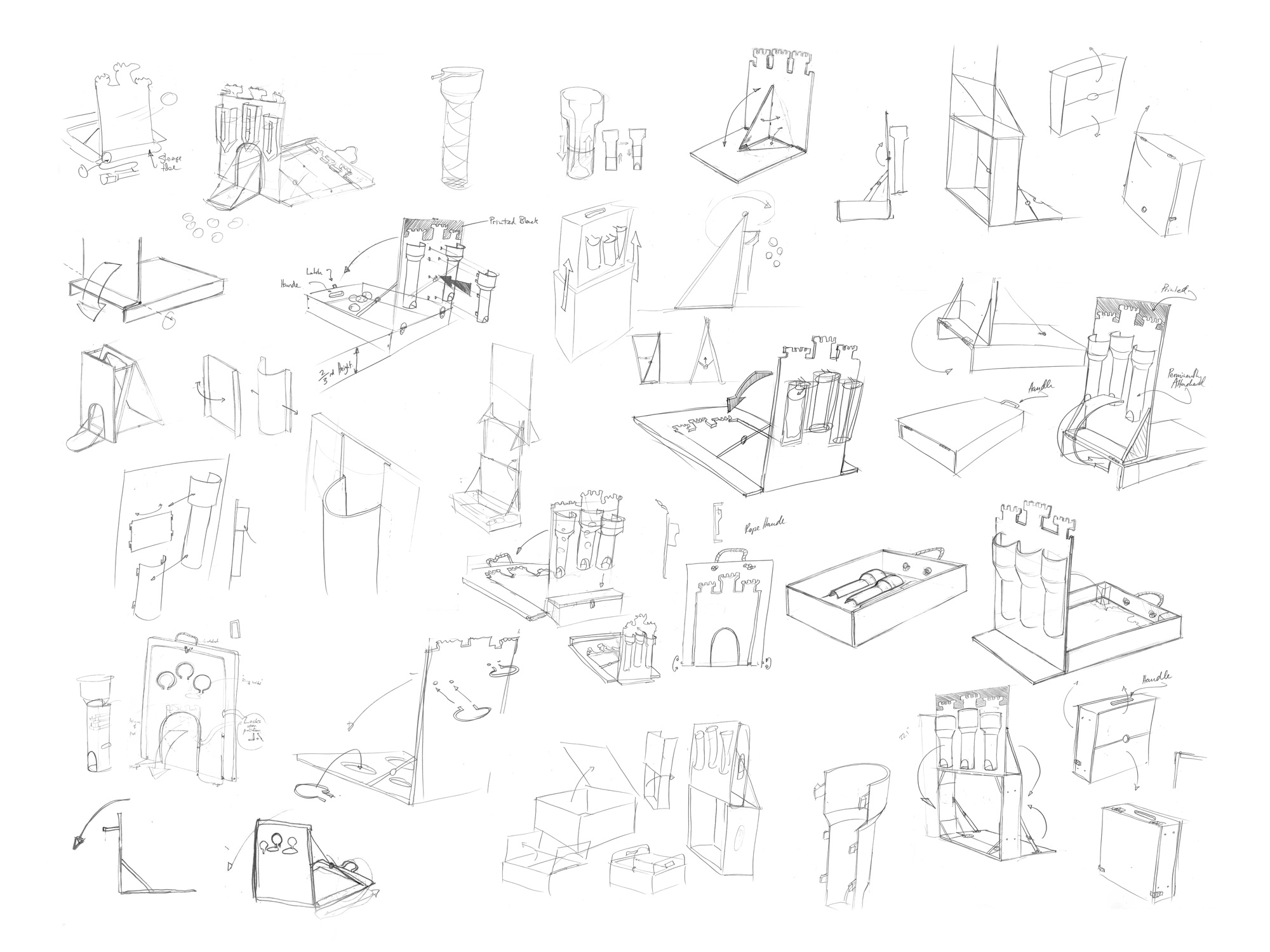

Ideation

The original version of Klooji was made from plywood and sold by word of mouth. Size and weight were significant problems for retail shelves. Having been play tested for years, however, the gameplay itself was well refined. Our challenge was to streamline the design to make it portable and feasible. Several brainstorming sessions and many sketches later, we had a few promising directions.

Design Refinement

We then analyzed the initial ideation, considering ease of deployment, user experience, manufacturing and assembly process, and ultimate size and weight. We refined the most promising direction for prototyping. Following a successful prototype, we refined the design further to prepare it for manufacturing. The final design features a panel that flips up to reveal the castles and a second panel flips back for stabilization. The production-ready design reduced volume and weight by over 60%.

Engineering and Manufacturing

As we learned from testing the original version, Kloojiing can get pretty intense. When the competition heats up, “tossing” becomes “hurling”, and bean bags fly at alarming speeds. Adding strength to injection molding parts of this size can be a tricky engineering task. We added reinforcement in strategic areas, balancing strength against weight and aesthetic impacts. With the design refined for manufacturing, we created release documents and worked directly with sourcing companies and vendors to realize the final retail product.