AAACK! Packs – 2015

Austin-based startup AAACK! Packs came to us for help in developing their concept into a product. Their concept was a webstore with a streamlined experience, where customers choose from a variety of medicines, sundries, and toiletries, and those items are delivered in a robust travel case. With endless possible combinations of ordered items, we were charged with designing a modular system that allows the pack to get bigger or smaller depending on the items ordered. Through our design process, we developed an adaptable solution; a self-contained supply pack that contains everything you need and nothing you don’t.

Driven by the project’s performance requirements and target production timeline, we developed a soft-goods solution for the product. This approach allowed us to quickly prototype in production-quality materials and avoid the long lead-times needed for tooling and production of hard plastic parts.

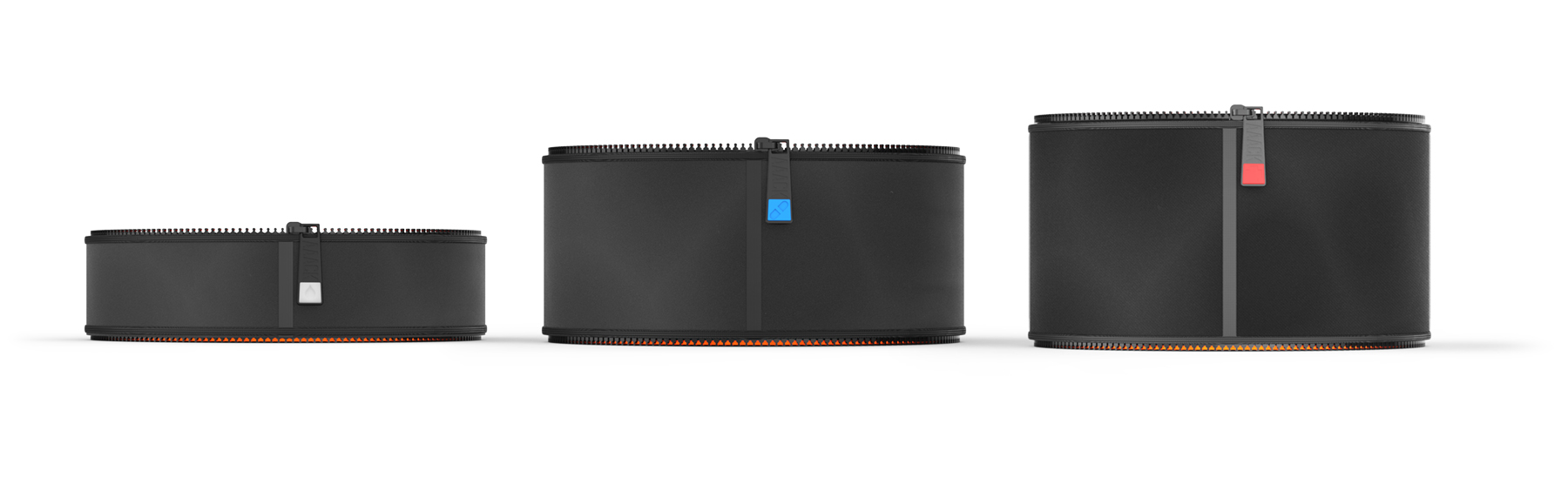

The resultant design of the AAACK! Pack system is a family of semi-rigid EVA foam cases with a neoprene outer and ballistic nylon inner. Internal mesh webbing holds items in place. Zippers line the edges of each compartment, allowing AAACK! to chain together multiple segments to increase the capacity of the system as needed. This approach easily adapts to each customer’s order. Additionally, customers can further customize their pack as they see fit. For example, a full height pack may live at home as a go-to for medical supplies, but a single compartment pack can be created temporarily for travel.

The final pre-production units were delivered less than 10 months after the first concept sketches were drawn. Our choices for production materials and methods and clear communication with skilled vendors brought AAACK! Packs to market ahead of schedule.